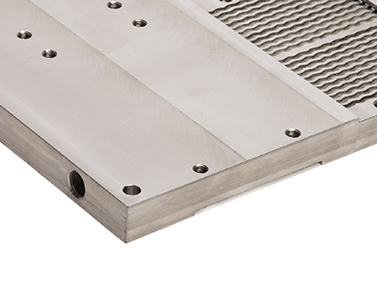

Through Controlled Atmosphere Brazing, Mecc.Al attains highly efficient heat dissipation for its most demanding projects and designs. This product range utilizes various aluminum alloys and is entirely engineered and manufactured within the company’s engineering division. Each individual part is meticulously customized using the latest Computational Fluid Dynamics (CFD) design software, ensuring meticulous attention to detail. In cases where it aligns with the client’s project requirements, controlled atmosphere brazing represents an advanced manufacturing technology specifically tailored for thermal management systems. It enables us to maximize plate design and cooling functionalities by employing specialized aluminum alloys.

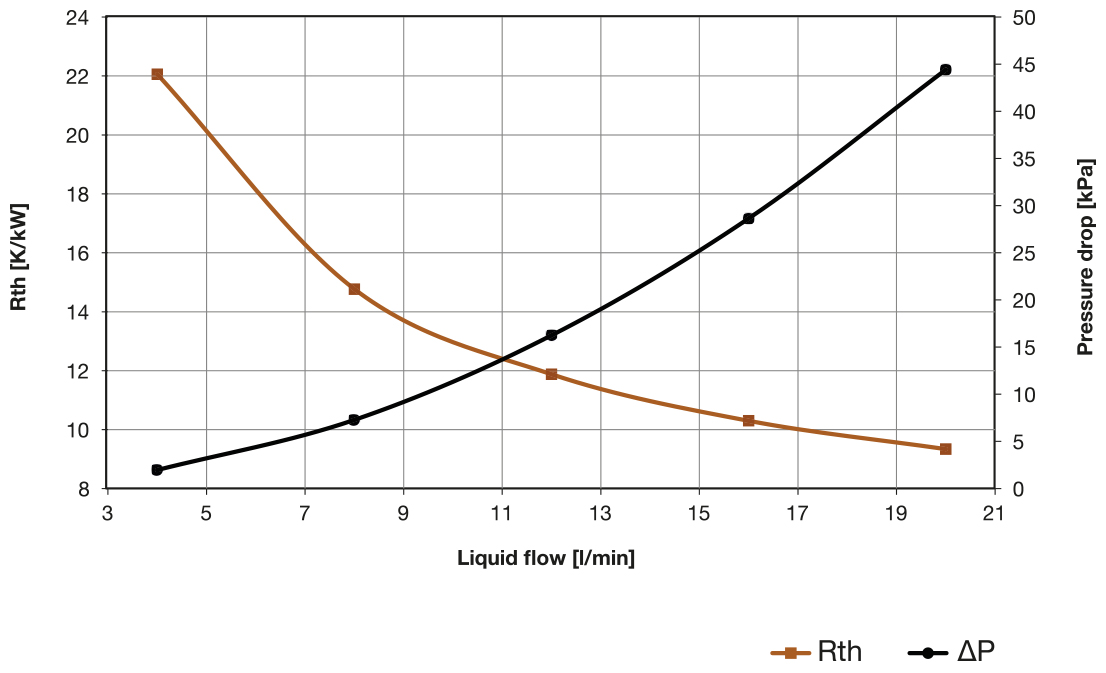

For projects demanding peak thermal performance, this technology ensures uniform cooling across the entire surface area occupied by semiconductors and active components.

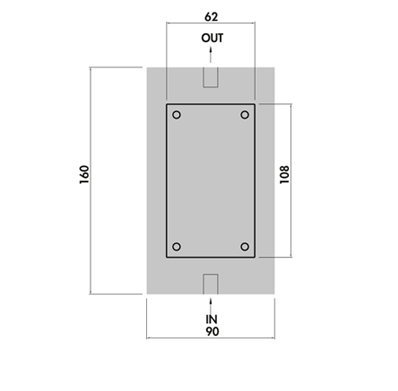

Developed by Mecc.Al’s Engineering Department, the internal channel designs, with or without turbulators, are meticulously crafted using sophisticated 3D design software and Computational Fluid Dynamics (CFD) simulations. This approach optimizes internal flow design and required pressure drop, allowing the construction of LCPs without limitations on internal or external shapes. CAB Plates can be equipped with connectors of varying types, diameters, and thread pitches, integrated or external to the plate.