Danotherm CBW resistors, designed for liquid cooling, boast compact dimensions compared to air-cooled counterparts. They excel in supporting high pulse loads and demonstrating exceptional vibration resistance.

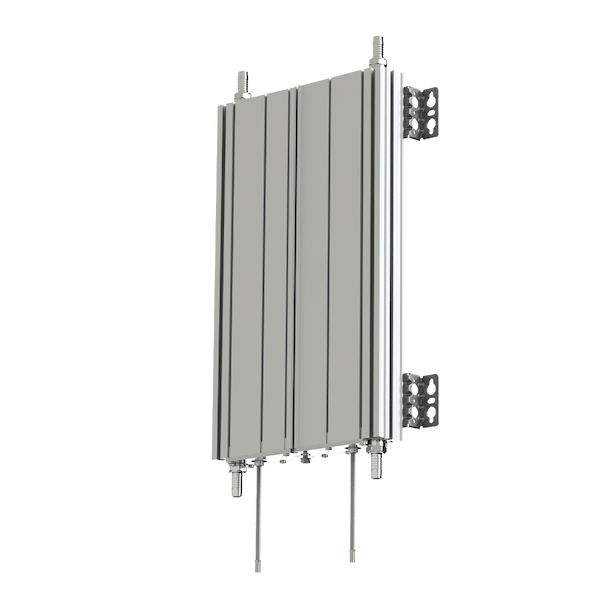

These resistors come equipped with fully-insulated aluminum housings featuring channels for liquid cooling. Their primary resistive components consist of wirewound spirals crafted from a Nickel-Chrome alloy renowned for its minimal thermal drift and precise electrical resistance characteristics. These resistive elements are encased in a filling material, either silicon oxide or aluminum oxide. This construction enables the resistors to function as thermal capacitors, possessing a high capacity for energy absorption.

The power ratings for liquid-cooled CBW resistors initiate at 860 W, contingent upon the water inlet temperature and flow. Their operational voltage ranges from 1000 VAC to 1400 VDC. Remarkably, these resistors can endure up to 60 times their nominal power rating during a 5-second pulse per hour, depending on the resistance value.

CBW resistors are offered in protection ratings varying from IP50 to IP65.

Customers can choose between a thermal switch or a PT100 element as optional features. Furthermore, customized versions with cable shoe connectors or DIN-rail terminals can be provided upon request.

Danotherm’s Liquid-cooled CBW resistors prove ideal for applications demanding high average power and/or significant pulse power loads. Typical use cases include serving as filter resistors for wind turbines, braking resistors for light rail and trams, and short-term load support for fuel cell applications. In traction applications, the heat generated can be harnessed for pre-heating driver and passenger compartments.