Reducing environmental pollution

Reducing environmental pollution is one of the biggest challenges we are facing today for a sustainable railway industry. There are many global policies on climate control, in particular related to low carbon transport and infrastructure where the main aim is to reduce emission within the mobility sector by 50% in the next few decades.

Emissions must decrease while the demands for transportation keeps increasing

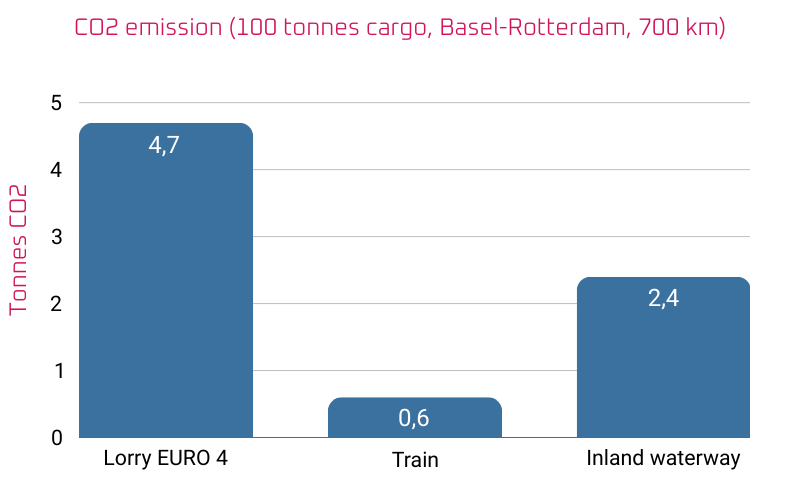

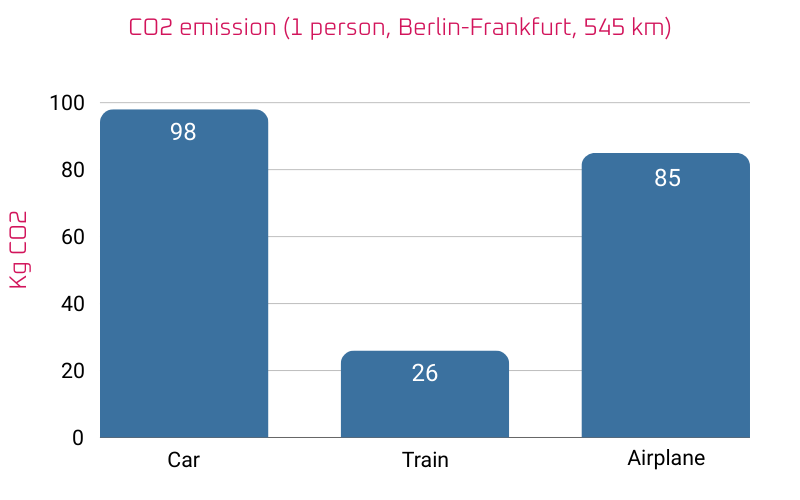

In order to meet the goal of keeping the global climate at a level below 2 degrees of pre-industrial levels, the emissions of greenhouse gases (GHG) have to go down, while the demand for transportation rises globally. Rail transport is already a quite efficient mode from an ecological and economical point of view. I have always believed that clear methodologies have to be formed to ensure the most resource-efficient way of operating this mode of transport in the future.

Figure: Rail emission compared with other modes of transport

Source: Ecotransit.org (global carbon footprint freight)

Until now, methodologies assessing the environmental impacts almost exclusively focus only on tailpipe-emissions produced by rail operation and neglected the emissions caused by producing, maintaining and disposing railway infrastructure. However, within the European rail network of over 200,000 kilometers resource consumption, extraction, construction, maintenance and disposal of railway infrastructure components produce huge environmental impacts. Hence, there is great potential for producing and choosing the most sustainable components within railway infrastructure from an ecological perspective.

Evolution of power electronics in railway applications

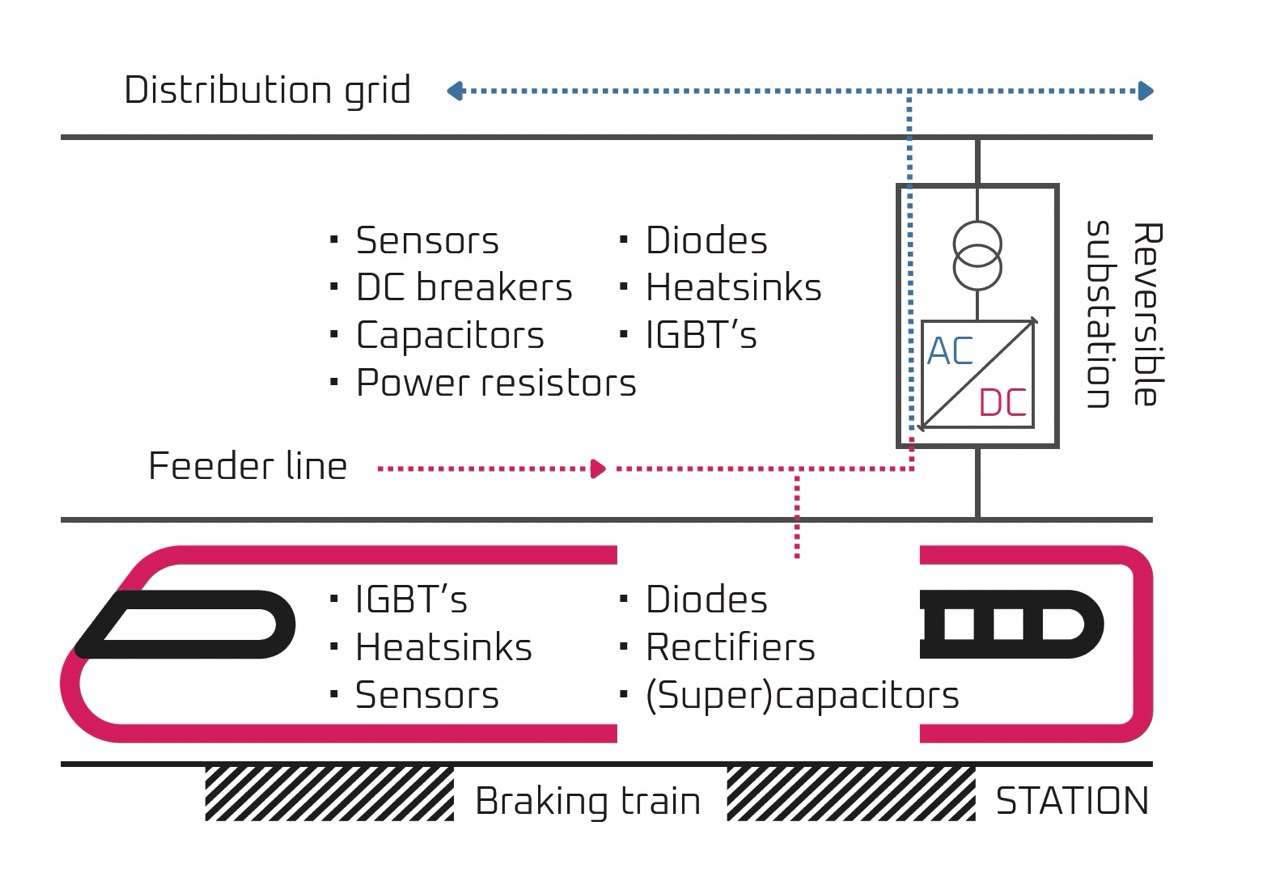

In relation to the development of electric railways, I must mention the evolution of power electronics technology. The replacement of rotary converters and mercury rectifiers with diode rectifiers to create DC-power caused a significant improvement in the operation and maintenance of DC traction substations. Power electronics equipment for railway applications include technologies that facilitate energy-savings and harmonization with the environment as well as provide the required degree of safety and reliability demanded from public transportation systems. In addition to these demands, the market needs a variety of improvements in efficiency, speed, size and weight savings.

For traction motor control of electric trains, the introduction of power semiconductor switching devices such as thyristors, transistors, gate turn-off thyristors (GTOs), and insulated gate bipolar transistors (IGBTs) and the evolution of power converter technologies have resulted in superior performance, reduced maintenance, energy saving, and downsizing.

It’s clear that the future of the railway industry is moving towards a greener direction. But what does that mean – particularly – for the sustainability front runners? Here, we take a look at some of the environmentally-friendly solutions that are currently taking shape in the railway traction industry.

The journey towards a sustainable railway industry is a bumpy but joyful ride.

IGBT

Insulated Gate Bipolar Transistors (IGBTs) are today’s cutting edge power electronics for the traction system of electric (and diesel-electric) railways. They replace the previous inverter generation served by GTO (gate turn-off thyristors). In contrast to conventional transistors, IGBTs operate at exceptional high currents (> 1000 A). The main advantage of IGBTs over GTOs is a much (3 to 4 times) higher switching frequency. This reduces the current required and therefore the heat produced, resulting into smaller and lighter units. The high switching frequencies additionally smoothens the acceleration process and reduces the traction noise.

IGCT

Unlike the maritime industry, the railway traction system shows much higher inductances when it comes to overhead line energy supply. This allows ‘slower’ semiconductors such as the Integrated Gate-Commutated Thyristor (IGCT), combining this reduced speed with much lower on-state losses. The IGCT technology based on the concept of the hard driven GTO, drastically reduces the storage time of the turn-off device to 1μs.This allows the powerful series connection of high-power turn-off devices. The homogenous operation, particularly during turn-off, allows the reduction or even removal of the dv/dt snubber. Together with a well-developed device design, the inverter losses and costs can be significantly reduced.

Circuit breakers

A power electronics component that has drawn my interest the most is the circuit breaker. Circuit breakers play an important role not only in the railway industry but also in the maritime industry from a protection and safety point of view. If this is taken care of in a proper way, downtime and risks can be reduced to the lowest possible level.

Mechanical DC breakers have been existing for a long time and are capable of interrupting DC currents within several milliseconds, but this is still too slow to meet the requirements of a reliable DC grid. DC breakers based on semiconductor technology can easily overcome the limitations of operating speed, but generate large transfer losses, typically in the range of 30 percent of the losses of a voltage source converter station. Sustainability frontrunners in the traction industry have already recognized this issue and presented a concept hybrid DC breaker that incorporates both mechanical and IGCT based characteristics, and are working on bringing the technology from concept to prototype level. Hybrid DC breakers not only improve reliability by speeding-up switching time but also reduce wear and tear resulting in less maintenance costs. If proven and scaled up, this technology has the potential to be the game changer for railway industry.

Illustration: A schematic overview of important power electronics components found in the reversible substation.

Conclusion

Advancements in design and innovation, especially in power electronics, are not only improving on existing rail applications, but are also developing new ones. The outcome is a more efficient, more reliable and sustainable railway industry that is far more cost-effective. As these products and systems are integrated across the rail sector, they could introduce a new era in rail travel of newly built networks as well as the established ones. The journey towards a sustainable railway industry is a bumpy (not really, since it is one of the smoothest ways of transport) but a joyful ride. A lot has been achieved and a lot will be achieved in the near and further future!

More about our solid-state DC breaker

Learn more about how our solid-state DC breakers offer optimal protection for your DC grid. Or view all our available solid-state DC breakers in our product catalog.